What is RTLS?

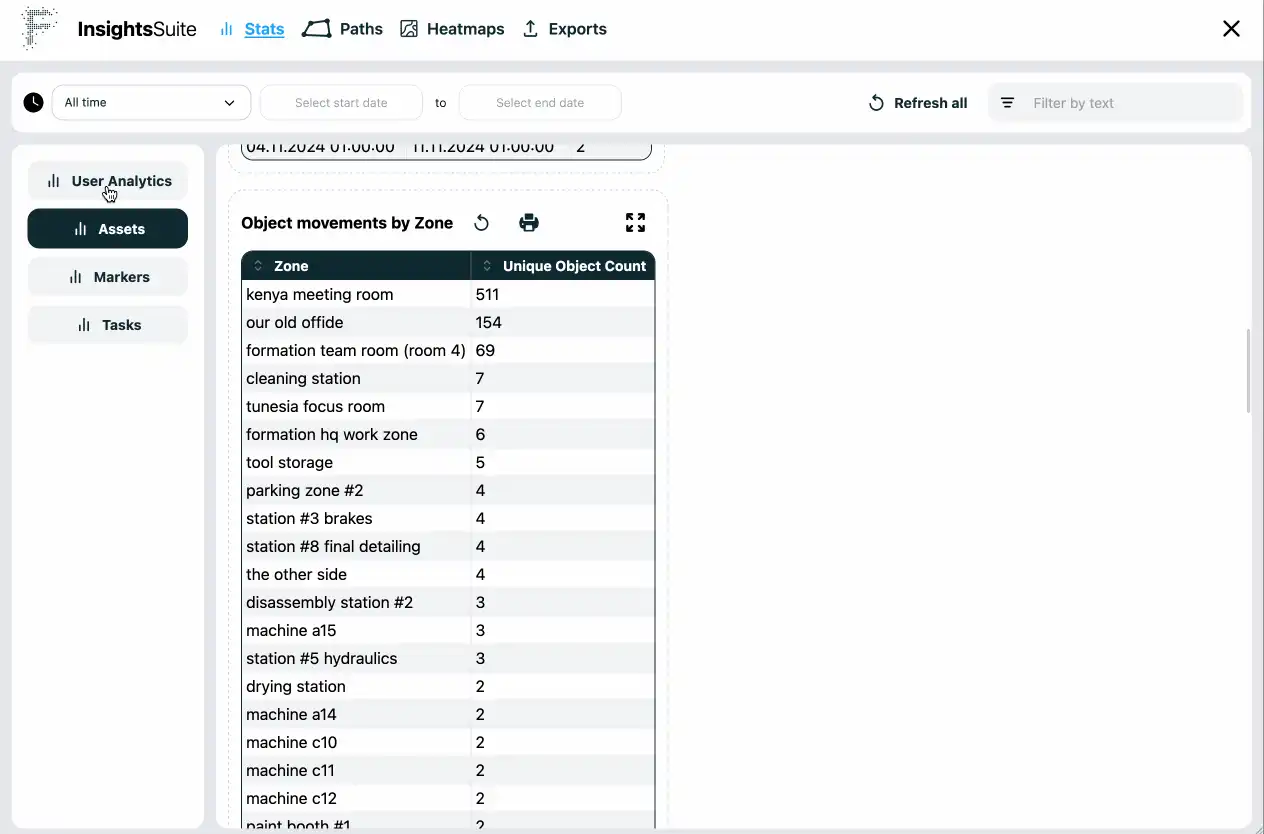

Real-time location data that turns movement into business insight

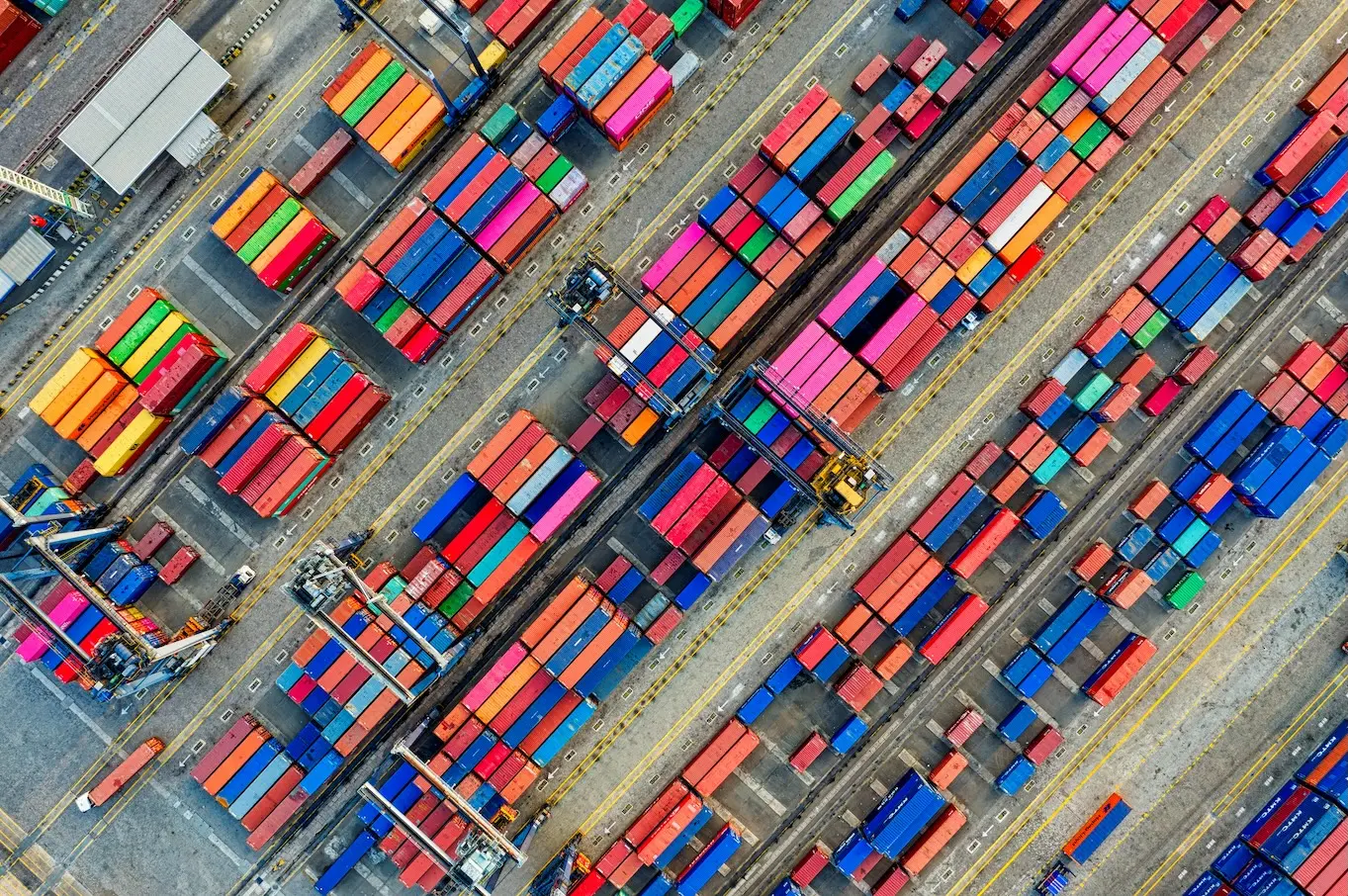

Real-Time Location Systems (RTLS) capture where things are. RTLS is not one technology. It is a family of solutions with different strengths. The right choice depends on what you track, where you track it, and how accurate or frequent the updates need to be.

Installing RTLS solutions typically involves selecting the right technology, deciding what areas to cover, deciding on the density of the tracking infrastructure, and configuring and calibrating the solution for the desired level of accuracy, the frequency of updates, and trading these decisions off against cost and battery life.

The core trade-offs

Battery life, anchors, accuracy, and frequency

- Battery life: Higher update frequency shortens battery life. Smaller tags also mean smaller batteries.

- Anchor density: Higher accuracy requires more anchors and tighter calibration. Increasing the density also lowers the distance to the location tags which means they need less energy to send updates.

- Location accuracy: Do you need room-level, rack-level, or centimeter-level precision? Do you need to know the altitude.

- Location frequency: Do you need a live path or just periodic updates? For example self driving vehicles in factories requite high frequency and highly accurate locations for real time decision making. For warehousing solutions the frequency is less important. And the accuracy depends on the size of the items you track. Some storage locations are large, others are smaller.

Cost drivers you should plan for

Hardware is only the beginning

- Anchors and readers: more accuracy usually means more devices and infrastructure. Some of this equipment might be battery operated and some of it might require networking and power.

- Site surveys and calibration: to get an accurate quote for an RTLS installation, this is always required.

- Service and maintenance: Battery replacements for anchors and tags. Replacement of faulty equipment. Dealing with accuracy issues in specific areas or adding more areas.

Power usage

A simple battery life model

Tag battery life is primarily driven by how often a tag transmits and how much energy each transmission consumes. Ignoring configuration details, average power usage can be described with the following model:

$$ P_{avg} \approx P_{idle} + f_{update} \cdot E_{update} $$Where P is power, f is update frequency, and E is the energy cost per update.

Battery life then follows approximately as:

$$ T_{life} \approx \frac{E_{battery}}{P_{avg}} $$This relationship explains most RTLS trade-offs: higher update rates and longer transmission ranges reduce battery life, while lower frequencies and denser infrastructure extend it. Battery life then follows directly:

Typical RTLS performance ranges

The ranges below reflect typical deployments. Actual performance varies by environment, tag configuration, and infrastructure quality.

| Technology | Typical battery life | Typical update frequency | Typical accuracy | Tag Cost | Infrastructure Cost | |